The content of the article:

- The importance of ventilation and insulation

- Choice of materials

- Mineral wool

- Glass wool

- Polyfoam / Penoplex

- Reflective insulation

- Paint / Plaster

- External insulation

- Internal insulation

- Gate insulation

- Roof insulation

Often the garage is used not only for parking a vehicle, but also as a workshop, warehouse and utility room. Such versatility requires a certain microclimate and high-quality thermal insulation.

The importance of ventilation and insulation

Even when operating a garage only for parking a vehicle, it must have the appropriate conditions to ensure the safety and durability of the vehicle.

The mandatory requirements for a high-quality microclimate include:

- maintaining a temperature of about + 5 ° in cold seasons, which is ideal for storing vehicles;

- ventilation system, supplying at least 180 cubic meters / hour for each unit of transport.

Some car owners try to provide room temperature in the garage, considering it favorable, but this opinion is fundamentally mistaken. Such conditions in winter will lead to inevitable condensation and, as a result, to the appearance of corrosion on the metal.

A very common mistake when carrying out insulation measures in the garage is the elimination of all possible places of penetration of external air into the room. And sometimes car owners even get rid of ventilation windows, depriving themselves of fresh air and harming their own health.

Choice of materials

Mineral wool

It is a very popular means of insulating a garage, allowing it to "breathe". For insulation work on the outer surface, mats with a higher stiffness of 200-240 kg / m3 are used, for the inner surface - less dense 120-180 kg / m3.

In terms of sound insulation and thermal conductivity, a variety of mineral wool, called basalt, is in the lead. Working with mineral wool requires a vapor barrier layer designed to protect the insulation from atmospheric moisture and maintain its performance.

The process of warming with mineral wool should be as follows:

- laying the hydro-barrier;

- a layer of mineral wool, fixed with dowels;

- another layer of hydro-barrier;

- finishing finish.

The approximate cost of such work in a standard garage will cost 15-16 thousand rubles.

Mineral wool is a very strong insulation, therefore it is most often applied to those garages that are directly adjacent to the house, being part of it.

Glass wool

The price tag for glass wool is significantly lower than for mineral wool, saving up to 25%. Working with this material will require the use of special gloves, as well as protection against moisture penetration, which causes irreversible damage to the fibers, their deformation and loss of functional properties. The method of laying this type of mineral wool is similar to the previous one, but it is not so popular among motorists precisely because of the difficulties associated with the specifics of the material.

Polyfoam / Penoplex

Foam insulation is characterized by simplicity, small mass of material and the level of water absorption, ease of processing and a budget price. They fix it to the wall using various methods, including using glue and polyurethane foam. Significant disadvantages include high flammability and yellowing when exposed to sunlight.

The cost of insulating the garage with polystyrene foam will be limited to 13-14 thousand rubles.

Penoplex is a modernized version of polystyrene, which is more dense and resistant to stress, less thick and flammable. So, a 3.5-centimeter foam is comparable to a 5-centimeter foam.

Installation technology is comparable to foam, but this material has connecting locks that protect against cold air penetration. The use of penoplex will cost a little more, but, given all the advantages, it is worth giving preference to it.

Reflective insulation

This material owes its appearance to the construction markets to innovative ideas in terms of energy conservation. One side is made of expanded polyurethane foam, and the other is made of polished foil. Like any material, it has its own disadvantages and advantages. It, in particular, is not used for outdoor work, it also does not provide enough protection against conduction and convection. But it is compact and environmentally friendly, has high thermal conductivity, is quite durable and non-flammable.

Working with reflective material depends on its type:

- type A is universal and is nailed to the wall with ordinary nails or special glue;

- type B has a double-sided coating, is fixed in the same way;

- type C has a self-adhesive base, which greatly simplifies the work with the material.

Paint / Plaster

Liquid heat insulators are good because at the same time they give the garage an attractive look. Their composition includes a base of acrylic polymers mixed with rubber and organic dyes. The consistency of the material is similar to the paint familiar to everyone, but only a 1 mm layer of this paint confidently replaces 50 mm of mineral wool.

It is applied to any surface and has a high vapor permeability. Warm plaster can be filled with foamed vermiculite, expanded polystyrene and sawdust. To create the desired heat-insulating effect, you will need to apply a very thick layer of such a plaster. Therefore, it is rarely used as an independent material, only in combination with some other insulation.

External insulation

Outside, the garage is preferable to insulate with foam, as a fairly reliable and budget material. In places of expected high-temperature exposure, for example, the operation of equipment or heating, plastic should be replaced with non-combustible mineral wool.

Preparatory work prior to the installation of foam boards consists in cleaning the walls, removing surface defects and priming.

In order to save money, the foam is often attached using a point method of applying a solution, to which the material is then pressed with significant pressure. Those motorists who do not save on themselves evenly distribute the adhesive solution with a spatula over all wall surfaces.

Plates are laid from bottom to top in a checkerboard pattern. For the first row, a strip is attached to the wall, and for maximum reliability, the laid plate is additionally attached with plastic dowels.

Not the highest strength of the material leads to the need for mandatory wall cladding. Plastering with fiberglass mesh reinforcement and then coating with paint, plaster or siding is suitable for this purpose.

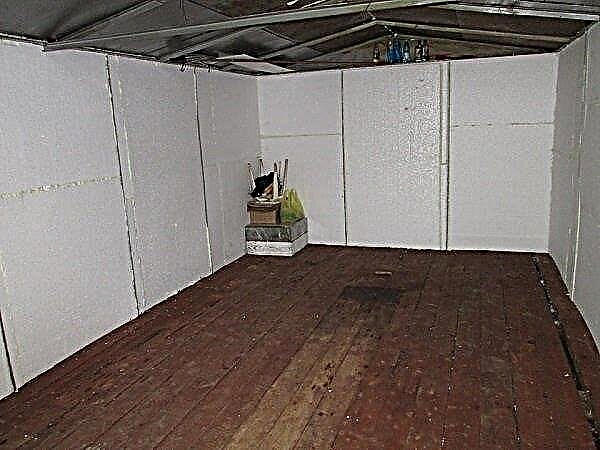

Internal insulation

The process of warming the interior of the garage is as follows. On the surface of the walls prepared in advance, a false partition is fixed, whose frame already has a heater. Drywall is often replaced by asbestos fiber, which has a high level of fire resistance, although it is more fragile.

Wadded materials are used as insulation, which are easier to install than polystyrene. A mandatory requirement will be the creation of a membrane vapor barrier.

Gate insulation

The likelihood of heat loss should be foreseen even when designing and purchasing garage doors. A wicket in one of the doors eliminates the need for frequent opening of the gate, which prevents cold masses from entering from the street.Additionally, an internal curtain made of fabric or plastic can be provided.

Further, the foam comes into play again, as the most optimal heat insulator. On the inner side of the gate, a specially designed lathing is attached, into which foam plastic plates are laid. The joints are masked with polyurethane foam.

After the door is insulated, condensation may form in the areas where the heat insulator comes into contact with the metal during operation. To avoid this, all metal parts are treated with a protective anti-corrosion coating and reinforced waterproofing is installed. Only then is the frame mounted, on which the sheathing is attached with wooden slats.

Roof insulation

A detached garage requires mandatory roof insulation, as well as regular prophylaxis against dampness and all kinds of leaks.

The technology for installing thermal insulation will directly depend on the material of the floors. The most practical and durable is the combined insulation, made using a classic material and a reflective heat insulator. But the cost of such work will be extremely high and not entirely justified.

In the case of a wooden base, use polystyrene, fixed with nails or dowels, and then veneer with an attractive material.

The concrete floor will require a frame reinforced with self-tapping screws and metal corners, on which the foam will be laid, fixing with adhesive tape for stable lying.

Fiber-based insulation requires high-quality hydro and vapor barrier.

For the roof space, polyurethane thermal insulation applied by spraying is excellent. It is a very fast, durable, moisture and fire resistant technology that hermetically fills voids and eliminates the need for additional vapor barrier. Immediately after spraying, you can start finishing work.