The content of the article:

- What it is

- Mechanism device

- Scheme

- Principle of operation and types

- Types of power steering

- Left or right hand drive

- Is the adjustment necessary

- Repair and parts price

- Possible breakdowns

The steering of a car can be considered the main mechanisms of the entire structure, in fact, without it, you cannot control the car. Given the progress of technology and the automotive industry, today there are several device options, as well as different locations in the car (left or right).

In a few words, it is a transmission mechanism, from the steering wheel and to the wheels of the car. To understand how the car control works, we will consider the principle of operation, the device and the main nuances that are most often encountered.

What is a car steering mechanism

The steering mechanism itself is considered the basis for driving a car. This is not a separate element, but a set of parts, mechanisms and assemblies that transmit the position of the steering wheel to the angle of rotation of the front wheels of the car. Regardless of the vehicle, the main task of such a set is to provide a turn, as well as to maintain the direction of traffic specified by the driver.

At the moment of turning the steering wheel, the tilt angle is transmitted by means of mechanisms to the rail, after which the wheels change position, respectively, and the direction of movement of the car changes. According to the structure, experts distinguish several types of swivel mechanisms for car wheels, while the result of the work will be the same.

Car steering mechanism device

Depending on the method of converting torque and steering wheel rotation, there are several options for the mechanism. Accordingly, the structure will be different. Among the main types, there is a rack and pinion mechanism and a worm gear, there is also a screw mechanism, but in structure it resembles a worm gear for many. On the other hand, the helical type of steering shows greater efficiency, which means that the effort is greater.

Regardless of the car's steering mechanism, most of the parts are the same. The list includes:

- steering wheel;

- column for transmitting the angle of inclination of the steering wheel;

- steering mechanism;

- control amplifier;

- drive unit;

- other additional elements (depending on the type of steering).

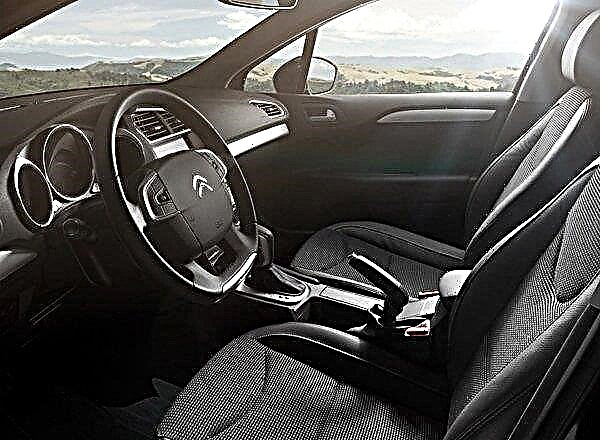

To understand what each of the pointed details is responsible for, let's consider them in more detail. Steering wheel an invariable detail, which any vehicle cannot do without, in cars it is most often round in shape. Depending on the country where the car will be used in the future, the steering wheel can be located on the left or right. The main purpose of the steering wheel is to indicate the direction of the car, by turning in one direction or the other. For comfort and safety, the steering wheel can be heated, adjustable for vertical and depth adjustment and with function buttons. In addition, steering paddles can be added while driving (automatic transmissions only).

Steering column plays an equally important role, the main task is to transfer the angle of inclination of the steering wheel to the wheel steering mechanism. As a rule, this is a shaft with swivel joints, but given the progress, the transfer of control can be made by an electric motor, at the expense of electronics. To provide additional protection against theft and additional security, the steering column may include a mechanical or electronic locking system. Also, many manufacturers install an ignition lock, steering levers, wipers and other necessary functions on the column.

For turning the wheels and further processing the torque from the column is responsible steering gear... It is this part, depending on the manufacturer, can have a different internal design. If we take a superficial inspection, then the structure consists of a gearbox and a transmission mechanism that connects the steering rack and column.

For the comfort of the driver and the preservation of the steering mechanism, the engineers added power steering... It is he who allows not only to increase the efficiency of transferring the steering force from the steering wheel to the drive, but also to soften this process, removing jerks and the load on the parts of the entire wheel turning mechanism. Another important element of the entire mechanism can be considered steering gear... According to the device, this is not one part, but a combination of several elements, as a rule, it includes steering rods, tips and levers. Concerning additional elements, then it all depends on the manufacturer and the suspension device.

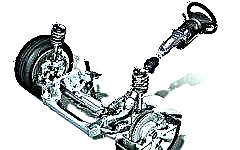

Car steering mechanism diagram

The photo shows a diagram of the steering mechanism of a car

- steering wheel;

- steering column;

- cardan shaft;

- amplifier motor;

- steering wheel rotation sensor;

- electronic steering control unit;

- wheel turning device.

The principle of operation and types of steering mechanisms

As already mentioned, there are three main types of steering mechanism: rack, worm and screw. The most common type on passenger cars is considered rack... The design is quite simple and has a good efficiency of transmission of steering torque (installed on a car with an independent suspension). The steering rack with a gear serves as the basis, while the gear itself is installed on the shaft and is constantly in engagement with the rack.

Rotating the steering wheel, the rack moves by the gear in a horizontal position to the left or right. The rods attached to the rail also move in accordance with the turn of the steering wheel, thereby transferring forces to the wheels and turning them to the sides. The main advantages are in the structure itself, fewer rods and hinges, compactness, low maintenance cost, simplicity of design and reliability. There are also disadvantages, the gearbox of such a mechanism is very sensitive to irregularities on the road, for which any impact of the wheel is transmitted to the steering wheel.

The second type of mechanism is worm... It is considered the oldest species among the existing options. Most often found on classic, domestic cars, as well as on vehicles with increased cross-country ability. As a rule, the suspension of such cars is dependent. The worm mechanism differs from the previous type by the presence of a worm roller, instead of a gear, a crankcase, as well as a steering bipod. In this control mechanism, the "worm" is located on the lower part of the steering shaft and is in constant engagement with the roller. Due to this design, the shaft turns, transmitting the force to the wheels of the car. The main advantages are the transfer of large forces, better maneuverability of the machine, minimal transfer of wheel impact to the steering wheel, as well as turning the wheels at a large angle, which other mechanisms cannot. Still, there are downsides, the design is very complex, and the maintenance costs money. In addition, the composition includes many connections that eventually deteriorate and require periodic adjustment.

The last of the types of steering - screw... Unlike the two previous types, the mechanism is connected using a nut and balls of a special screw. As practice shows, the wear of such a mechanism is minimal, and parts break very rarely.

Most often, the screw mechanism is used on trucks, buses and luxury cars with increased comfort and safety.According to the principle of operation, the screw subspecies works in the same way as the worm gear, transmitting the moment of turning the steering wheel through the worm gear.

Types of steering gear amplifiers

To facilitate driving and improve comfort, engineers have added power steering to the steering mechanism of the car. There are three main types of steering boosters: hydraulic booster, electric booster and electrohydraulic booster.

Hydraulic power steering (also known as power steering) is considered the most common among all existing ones. The main advantage is considered compactness, maintainability and simplicity of design. There is a minus, it is constantly necessary to monitor the level of the working fluid.

The second option for power steering - electric (EUR)... Today it is the most progressive mechanism, due to its device it provides easy adjustment, reliability in operation and economical in terms of fuel consumption (engine load). The main and huge plus is the ability to drive a car without the participation of the driver.

The last, third version of the power steering - electrohydraulic (EGUR)... It is based on the principle of operation of a conventional hydraulic amplifier, but in this embodiment, the pump is driven by an electric motor drive, and not an internal combustion engine, as in the first version of the amplifier.

Due to the structure and various possibilities, the manufacturer can supplement the control mechanism with an active steering system (AFS), dynamic or adaptive control.

Features of the left and right steering wheel

It will come as no surprise to anyone that the steering wheel in a car can be on the right or left. This factor is influenced by the country of car production and the place of its operation. As statistics show, in most of the countries of the world the movement is right-hand, respectively, the steering wheel is located in the car on the left.

In addition to the external location of the steering wheel, the steering gear is adapted to it. On the other hand, practice shows that it is absolutely possible to convert the steering wheel from one side to the other. This is especially convenient on vehicles where there is a so-called hydrostatic control system. Then it is simply necessary to rearrange the steering wheel itself, the steering universal joint and replace the front panel, the rotary set under the hood does not require modifications or changes.

Do I need to adjust the steering mechanism

A novice car enthusiast may ask if it is necessary to adjust the steering elements, the answer is unequivocal - yes. Often the rack gear and the worm element need adjustment. It is in these details that a backlash may appear at the time of operation, which will entail rapid wear of other elements, most often the breakage of the rail or nearby mechanisms.

As a rule, adjustment of the steering mechanism must be carried out only at specialized service stations and exactly according to the manufacturer's regulations. If more than necessary to tighten the parts of the mechanism, this can lead to partial or complete seizure, at the time of turning the steering wheel, to one of the extreme positions. Such "repair" can lead to loss of control and unpredictable consequences.

The cost of repair and parts of the mechanism

Since the basis of the car's steering has moving elements, accordingly they fail over time, despite the quality and initial cost of the elements. Before proceeding with the repair, it is necessary to undergo diagnostics and the more complex the design of the car, the more expensive the necessary procedures will be. On average, the diagnosis of the elements of the mechanism will cost from 400-700 rubles.

| Average cost of repairing steering components | ||

| Name | Price from, rub. | Price from, UAH |

| Repair of a steering rack with EUR | 5000 | 2000 |

| Repair of the rack with power steering | 6250 | 2500 |

| Repair of the rack without power steering | 4500 | 1800 |

| Rail distributor repair | 3000 | 1200 |

| Sleeve housing rail | 2500 | 1000 |

| Replacing the crosspiece | 2250 | 900 |

| Gearbox repair (truck) | 13750 | 5500 |

| Gearbox replacement | 8750 | 3500 |

| Replacing the power steering pump | 1750 | 700 |

As for the cost of parts of the mechanism, much depends on the brand, model of the car, the device of the elements and other factors.

| Steering gear parts price | ||

| Name | Brand, model, year | Price from, USD $. |

| Rail | Suzuki Grand Vitara 2008 | 445 |

| Steering shaft cross | Suzuki Grand Vitara 2008 | 7 |

| Cardan shaft | Suzuki Grand Vitara 2008 | 78 |

| Steering shaft cardan | Lexus LX 570 2009 | 118 |

| Rail | Subaru Forester 2002 AWD | 1235 |

| Cardan shaft | Infiniti FX35 2008 | 55 |

Major malfunctions and causes

There can be many options for steering failure, and it is almost impossible to predict each one. Nevertheless, experts highlight the main details that most often fail:

- wear of the bearing of the power steering pump shaft;

- slipping of the power steering belt;

- low level of working fluid;

- depressurization of the system;

- traction wear;

- gear-rack wear.

The reason for the breakdown or rapid wear of these parts is most often bad roads, untimely maintenance and repair of the mechanism. The limiting life of parts comes much less often. The main signs of such malfunctions are considered to be knocking in the steering, beating on the steering wheel, steering play, noise in the power steering and leakage of power steering fluid. Depending on the breakdown, you need to look not only for the faulty part, but also the source of the cause of the breakdown. This is usually one or a series of parts that will cause subsequent damage to new and replaced parts.

As you can see, there are many types and different steering devices. But, despite this, it performs the same task - the choice of the direction of movement of the vehicle. With the advancement of automobiles, the basis of control only improves, an example of which is electric vehicles, where more and more often they are starting to use an electronic-based mechanism. This means the perspective of development for the species where the set of mechanical connections and details is absent or minimized.